The world of dentistry is not complete without the mention of aligners, retainers, bridges, dentures, and splints. These are used to replace or give support to any broken or missing tooth. However, a dental digital impression is all that is needed to create a 3D printed model in the first place. The blog offers a guide to know how 3D printing of models can be obtained. This is a step in the future as opposed to the conventional physical impressions that dentists across regions and time are wont to use.

Physical impressions versus digital impressions

Traditionally dentists use alginate materials to prepare models of the broken or missing tooth. The process can be quite cumbersome, time-consuming and a sort of ordeal for the patients. This is because the materials are needed to be held firmly by the patients in their teeth to get the right impressions. Unfortunately, the process is not without its share of issues, for patients can be prone to gagging or swallowing the material. Also, if the impressions do not come out right the first time, the process needs to be repeated leading to further frustration. No wonder, patients are often found to be anxious when told to undergo the traditional process of obtaining dental impressions.

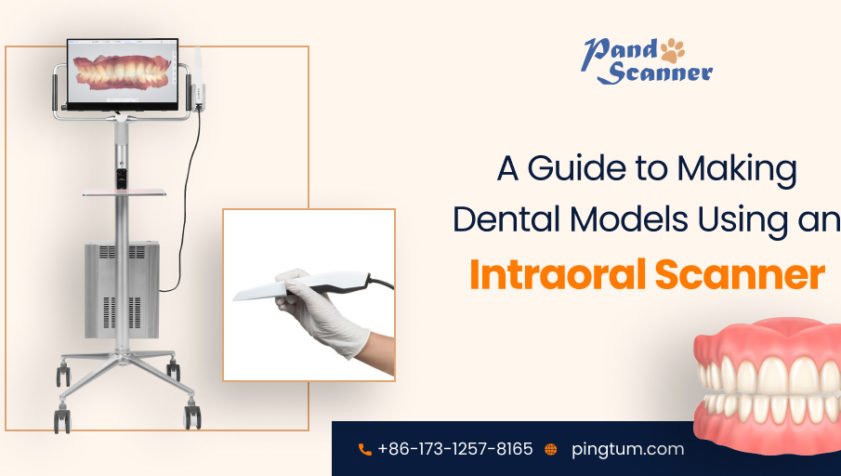

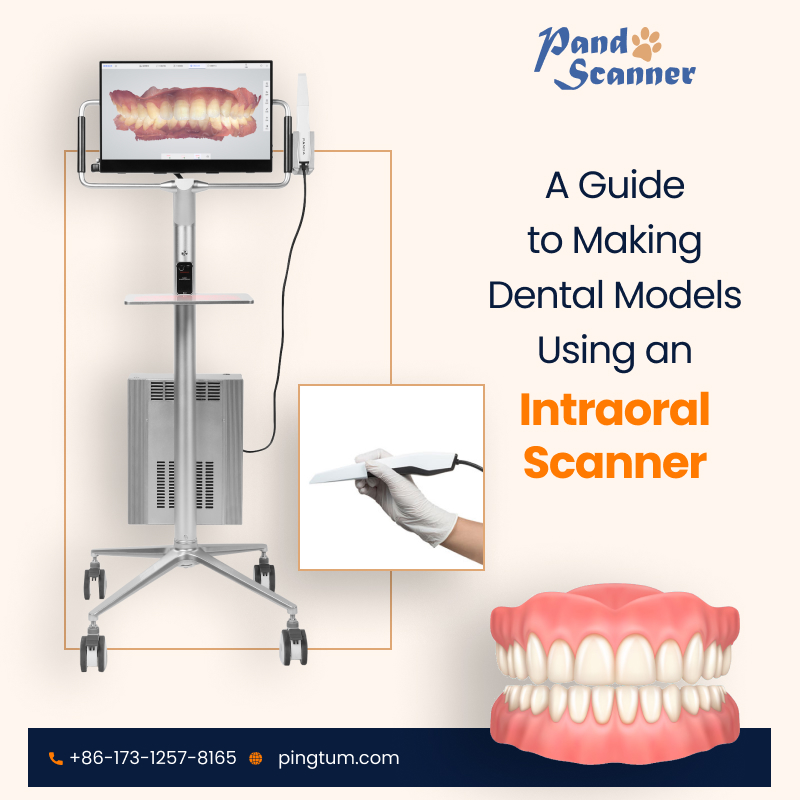

Obtaining a digital impression, on the other hand, can be a seamless affair. A digital model can be obtained by scanning the patient’s teeth with a dental intraoral scanner. It is a handheld device that emits light on the area to be scanned wherein the sensors capture multiple images to create a 3D digital model. Alternatively, the alginate impressions are scanned with a desktop optical scanner in a dental lab to prepare 3D models. Since intraoral scanners are quicker at obtaining dental impressions than a conventional system, there are cost savings due to reduced chair time. Besides, the whole process is far easier, simpler, quicker, and more comfortable for the patients. The best part, the dentist does not need to send the physical impression to a laboratory. Instead, he or she can send the digital files.

A step-by-step process to create dental models digitally

3D printing of aligners, crowns, dentures, restorations, bridges, or splints can be done from intraoral scans. The procedure involves four steps as mentioned below:

Scanning: Take multiple images of the buccal cavity using a dental intraoral scanner or obtain scans of a physical model using a desktop scanner.

Designing: Transfer the scanned images to the computer where a CAD software processes and same and builds a model to the exact specifications or dimensions.

Printing: Post designing the model of the broken/missing tooth, the digital files are sent to a 3D printer for printing.

Preparation: After the 3D printing of the model is over, wash and then dry the same to be fitted in the mouth of the patient.

Thus, digital 3D printing is more efficient and quick than preparing models of stone or any alginate material a la traditional method.

Conclusion

3D printing and the use of a dental intraoral scanner can speed up the modeling process and reduce the associated costs. Even though working with CAD software may appear to be challenging at first, a short training can make it easy for the stakeholders to operate. Besides, installing such a scanner in the dental clinic can deliver a superior patient experience and attract greater patient footfall.